In today’s fast-paced manufacturing world, digital design and cnc sheet metal fabrication work closely together to create accurate and efficient results. It all begins with a computer-generated design — a blueprint that transforms ideas into real products. Engineers and designers use digital tools to plan every cut, bend, and punch before a single piece of metal is touched.

This combination of design and fabrication allows businesses to create everything from small custom parts to complex industrial components. With cnc sheet metal fabrication, precision is guaranteed because machines follow exact digital instructions. This connection also helps reduce errors, improve quality, and speed up production.

Why It Matters for Modern Businesses

Digital design is no longer just for big companies. Even small workshops are using it to bring creative projects to life. By connecting computer-based design with CNC machines, fabricators can work faster, make cleaner cuts, and produce detailed parts that meet exact measurements.

It’s not only about efficiency — it’s also about innovation. The link between digital design and cnc sheet metal fabrication opens new possibilities for designers, engineers, and manufacturers who want to create better, smarter, and more sustainable products.

From Digital Design to Reality: How It All Begins

Turning 3D Designs into Real Parts

The process starts with engineers using CAD (Computer-Aided Design) software to create precise 2D or 3D models. These digital files include every detail — size, shape, thickness, and even material type. Once the design is complete, it’s converted into data that CNC machines can read.

This seamless handover ensures that the machine performs exactly as designed, cutting and shaping metal with pinpoint accuracy. It removes the need for manual measurements or guesswork, making production much faster and more reliable.

Why Digital-to-Physical Saves Time and Reduces Errors

In traditional fabrication, even a small measuring error could cause waste or rework. But with cnc sheet metal fabrication, the digital design acts as a perfect guide. The computer sends direct instructions to the cutting, punching, or forming machines, leaving no room for mistakes.

This process doesn’t just save time — it also improves product consistency. Every piece that comes off the machine is identical to the design file. For businesses, that means better quality control, faster turnaround, and more satisfied customers.

The Role of Laser Cutting and Laser Cutting Service in Precision Work

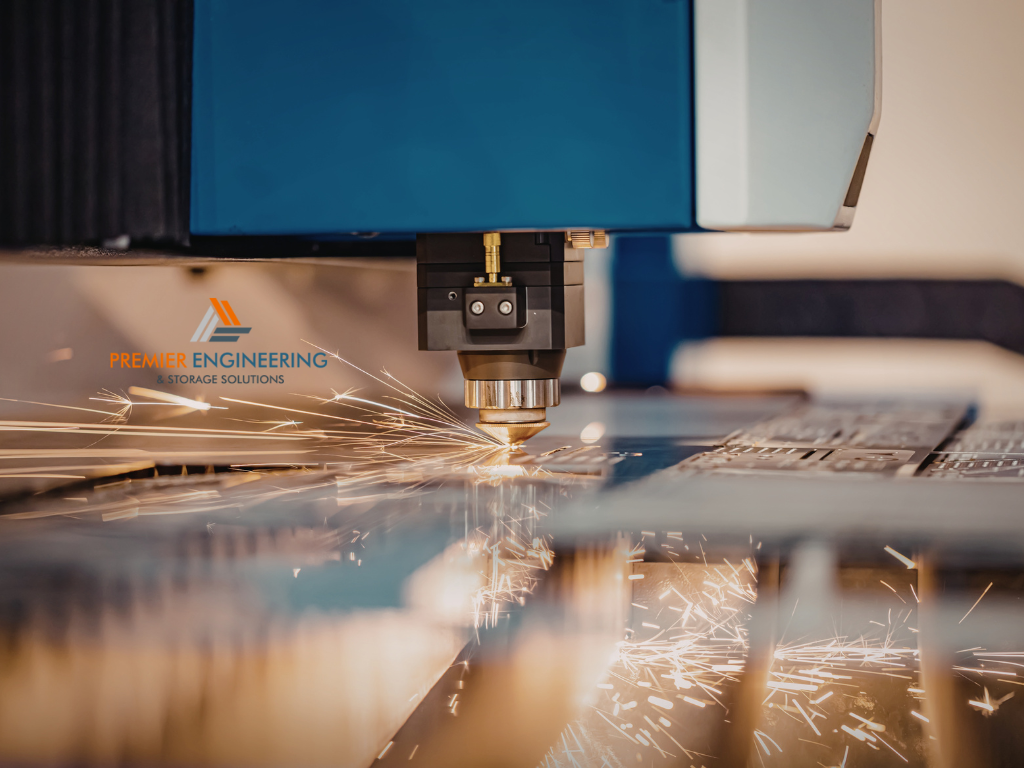

How Laser Cutting Brings Accuracy and Speed

When it comes to clean edges and perfect detail, laser cutting is the go-to technology. It uses a focused beam of light to cut through metal, creating smooth edges and precise shapes. Designers can upload their digital files, and the machine follows the path exactly, cutting even the most complex patterns effortlessly.

A laser cutting service makes this process accessible to everyone — from small businesses to large manufacturers. Whether it’s signage, parts, or decorative panels, laser cutting offers fast results with excellent quality. It also reduces the need for finishing, since the edges come out smooth and ready to use.

Why Laser Cutting Service Is Cost-Effective

Using a laser cutting service saves businesses time and money. There’s no need to invest in expensive equipment or maintain heavy machinery. By outsourcing, companies can focus on design and creativity while experts handle the technical work.

The precision of laser cutting also means less wasted material. Every cut is planned digitally, ensuring accuracy and efficiency. This technology supports both small-batch custom projects and large production runs — making it one of the most flexible and reliable methods in modern fabrication.

How CNC Punching Service and Metal Punching Services Fit In

How Punching Improves Precision and Efficiency

Alongside laser cutting, both cnc punching service and Metal punching services play a big role in modern metal fabrication. These methods are used to make holes, slots, and detailed cutouts in sheet metal — all controlled by computer data. Because everything is guided by the digital design, every punch lands exactly where it should, ensuring accuracy across every piece.

Unlike manual punching, cnc punching service uses automated machines that can perform complex tasks quickly. This helps reduce production time, especially for parts that need multiple cuts or patterns. The result is high-speed manufacturing with consistent quality, no matter how many pieces are produced.

Why Combining Punching and Laser Cutting Works Best

When Metal punching services are combined with laser cutting, manufacturers can achieve both flexibility and speed. Punching handles repetitive shapes or large holes, while laser cutting focuses on detailed patterns and fine edges. Together, they make production faster, cleaner, and more cost-effective.

This approach is perfect for businesses that need durable parts with smooth finishes and exact dimensions. The combination also helps reduce material waste, making it a smarter and more sustainable way to produce metal components.

The Power of Turret Punching Services in Modern Fabrication

Why Turret Punching Services Are Essential for Precision Work

In the world of cnc sheet metal fabrication, turret punching services are essential for creating detailed, repeatable parts efficiently. A turret punch machine uses multiple tools that can switch quickly between punches to make different shapes — such as circles, slots, or complex perforations — all from the same setup.

This versatility allows small and large manufacturers to complete projects quickly without constant tool changes. The accuracy of turret punching services also makes it ideal for prototypes, small runs, and large-scale production. It’s one of the reasons modern fabrication can deliver faster results while maintaining high precision.

Where to Find Reliable CNC and Punching Services

If your business needs expert metal fabrication, Premier Engineering & Storage Solutions is a trusted name in the industry. They offer a wide range of services including laser cutting, cnc punching, turret punching services, and Metal punching services.

Beyond fabrication, they also provide Shelving Units and Storage Cabinets, along with custom Machining solutions. Whether you’re a small business needing precise components or a large manufacturer looking for full-scale production, Premier Engineering & Storage Solutions delivers professional service, accuracy, and quick turnaround — all backed by years of experience.

Why Digital Design Improves Quality and Reduces Waste

Consistency Through Digital Accuracy

Digital design ensures that every project starts with the correct measurements and specifications. In cnc sheet metal fabrication, this means machines work from perfect digital data rather than manual instructions. The result is fewer mistakes, less rework, and more consistent results across batches.

By using technologies like laser cutting service and cnc punching service, manufacturers can guarantee that each part meets the same high standard. Every detail is digitally verified before production, helping save time and prevent errors.

Reducing Material Waste and Saving Costs

One of the biggest advantages of digital design is its ability to plan cuts efficiently. The software can optimise sheet layouts, ensuring minimal scrap material. This not only saves money on raw materials but also supports sustainable manufacturing.

When combined with Metal punching services and laser cutting, digital design helps companies deliver quality work faster, with less environmental impact. It’s a smart, modern approach that benefits both businesses and the planet.

The Future of CNC Sheet Metal Fabrication and Digital Manufacturing

Smart Manufacturing and Automation

The future of cnc sheet metal fabrication is digital, automated, and intelligent. Machines are becoming smarter, able to adjust in real time for accuracy and efficiency. Cloud-based design sharing allows teams to collaborate from anywhere, speeding up production and improving communication between designers and fabricators.

Artificial intelligence and smart software are already helping predict maintenance needs, track production performance, and improve energy efficiency. This means fewer delays, higher productivity, and better use of materials.

Embracing Innovation for a Better Tomorrow

As technology continues to evolve, the partnership between digital design and CNC fabrication will only grow stronger. From laser cutting service to turret punching services, each process is becoming more efficient and sustainable.

Businesses that adopt these tools now will be better prepared for the future — with improved precision, faster production, and lower costs. Embracing cnc sheet metal fabrication today means building a stronger, smarter, and more innovative future for manufacturing.