A cnc cutting machine is a powerful tool that uses computer control to cut and shape materials like metal, wood, and plastic. “CNC” stands for Computer Numerical Control, which means the machine follows a digital design file to make accurate and clean cuts—without needing to be operated by hand. It moves with precision, guided by software instructions, allowing for very detailed results.

What makes it special is how little human effort is needed once it’s set up. You upload a design, adjust a few settings, and the machine does the rest. This cuts down on mistakes, speeds up the process, and ensures every item turns out the same. Whether you’re making one item or one thousand, a cnc cutting machine can handle the job smoothly.

Why It’s Becoming a Must-Have in Modern Manufacturing

In today’s world, speed and accuracy are everything. Companies across industries—big or small—are turning to cnc cutting machines because they help them deliver products faster, with better quality and less waste. Manual cutting can be slow, uneven, or even dangerous, but CNC offers a safer and much more efficient option.

Another reason it’s a game-changer is versatility. You can cut simple panels or shape intricate designs with ease. Whether you’re creating signage, kitchen hardware, auto parts, or custom panels, a cnc cutting machine can do it all. And because it works with a range of materials, from soft plastics to hard metals, it’s become a go-to tool in almost every industry.

Businesses looking to grow, cut costs, or offer custom designs are quickly adopting CNC technology. It’s not just a fancy piece of equipment—it’s a smarter, faster way to build the future of manufacturing.

How Do cnc cutting services Help Small and Large Businesses?

Custom Parts Made Fast and Affordably

Whether you’re a small shop making prototypes or a large company producing at scale, cnc cutting services make the process easier. These services use high-tech machinery to take your design and turn it into real parts—fast. Instead of handling all the work in-house, you can get what you need from a reliable cutting provider without buying the equipment yourself.

Why Outsourcing cnc cutting services Makes Sense

Outsourcing saves you time and money. You avoid the cost of machines, maintenance, and training. Most cnc cutting services offer support for one-off jobs or high-volume orders, so you’re not locked into long-term contracts. They also ensure precise cuts that match your drawings every time, which helps maintain quality and reduces waste.

Why cnc stainless steel Is Leading in Custom Fabrication

Strong, Reliable, and Clean

When it comes to long-lasting materials, cnc stainless steel is hard to beat. It’s strong, rust-resistant, and easy to clean—perfect for industries like food, medical, and construction. Thanks to CNC precision, stainless steel can be cut into detailed shapes without damaging the material.

Where cnc stainless steel Shines

You’ll find cnc stainless steel used in everything from commercial kitchens and medical tools to structural components and machine parts. Its durability and clean finish make it a favourite among manufacturers who need parts that perform well and look great.

How laser cutting Works Alongside CNC Technology

What Makes laser cutting Unique

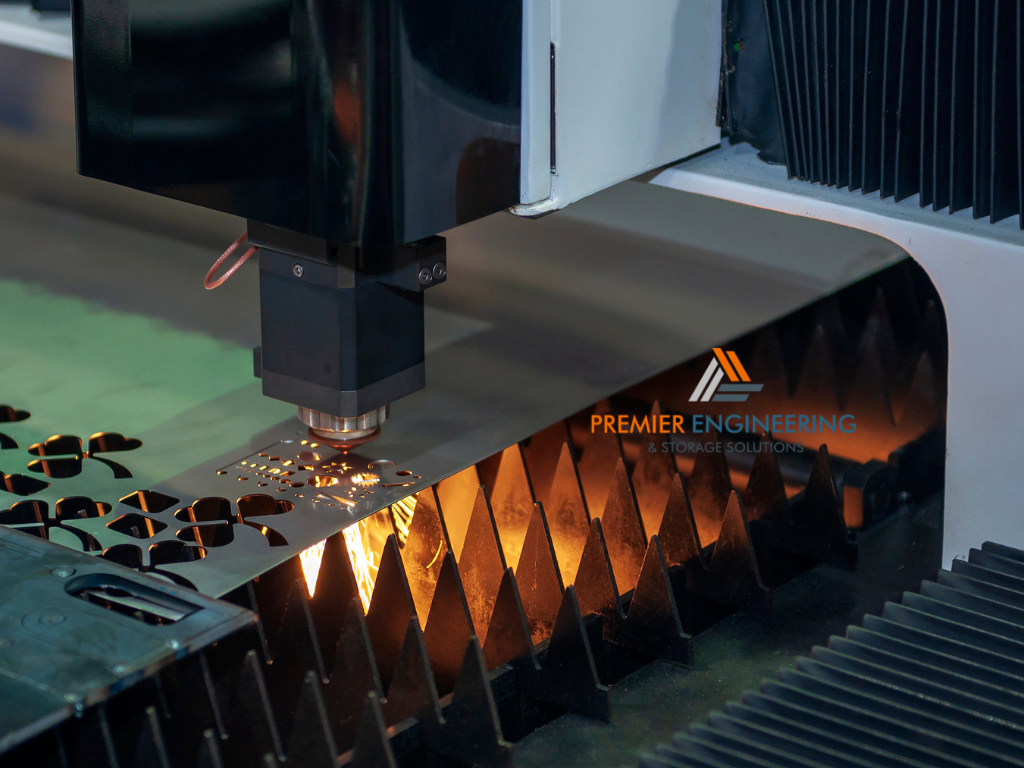

While a cnc cutting machine uses physical tools, laser cutting relies on a high-powered beam of light. That laser can cut through metal and plastic with incredible precision. It’s perfect for thin materials or complex shapes where a blade might struggle.

When to Use laser cutting

Laser cutting is ideal when you need detailed designs or minimal material waste. It’s often used in signage, electronics, or fine metalwork. When combined with CNC tools, it offers a full range of options for both heavy-duty and high-detail jobs.

What Makes an industrial steel cutting machine So Precise?

Built for Strength and Accuracy

An industrial steel cutting machine is designed to handle large metal sheets with pinpoint accuracy. These machines use CNC technology to follow digital instructions, ensuring every cut is smooth and exact. Their sturdy build allows them to cut thick or hard materials without losing precision.

Trusted by Leading Manufacturers Like Premier Engineering

Companies like Premier Engineering & Storage Solutions rely on industrial steel cutting machines to deliver high-performance results. They offer not only laser cutting and turret punching services, but also metal punching, machining, and custom shelving units and storage cabinets. Their team uses advanced tools to handle both one-off designs and high-volume production—making them a go-to for industries needing quality, speed, and reliability.

What Can Be Made with CNC Today That Wasn’t Possible Before?

Creative and Complex Designs

Modern CNC tools can make things that were once too difficult or costly. Think artistic furniture, precision aerospace parts, detailed engravings, and high-tech prototypes. The accuracy of a cnc cutting machine opens the door to endless possibilities.

One-Off and Custom Work Made Easy

CNC isn’t just for big factories. Artists, designers, and inventors can use it to bring unique projects to life. Whether it’s a metal sign, a bike part, or a custom frame, CNC makes it possible to create just one—without huge costs.

Is CNC the Future of Custom Manufacturing?

More Than Just Fast Cutting

CNC is changing how products are made. It’s not just about speed—it’s about smarter, more flexible production. Businesses can scale quickly, reduce mistakes, and adapt designs without slowing down.

Boosting Local and Global Manufacturing

From local workshops to global factories, CNC tools are raising the bar. They help companies reduce material waste, improve consistency, and offer better pricing to customers. Whether you’re making 1 or 10,000 parts, a cnc cutting machine makes it possible.