A cnc cutting machine is well known for its high level of accuracy. Unlike manual cutting methods, which depend on the skill and steadiness of the worker, CNC technology is controlled by computer programming. Every cut is based on a digital design, which means the machine follows exact instructions down to the smallest detail.

This level of control ensures that every piece produced matches the original design perfectly. Whether it’s a straight cut, a detailed curve, or a complex pattern, the cnc cutting machine repeats the same result again and again without mistakes. This is why industries that need flawless production, such as automotive, aerospace, and metal fabrication, rely on CNC technology.

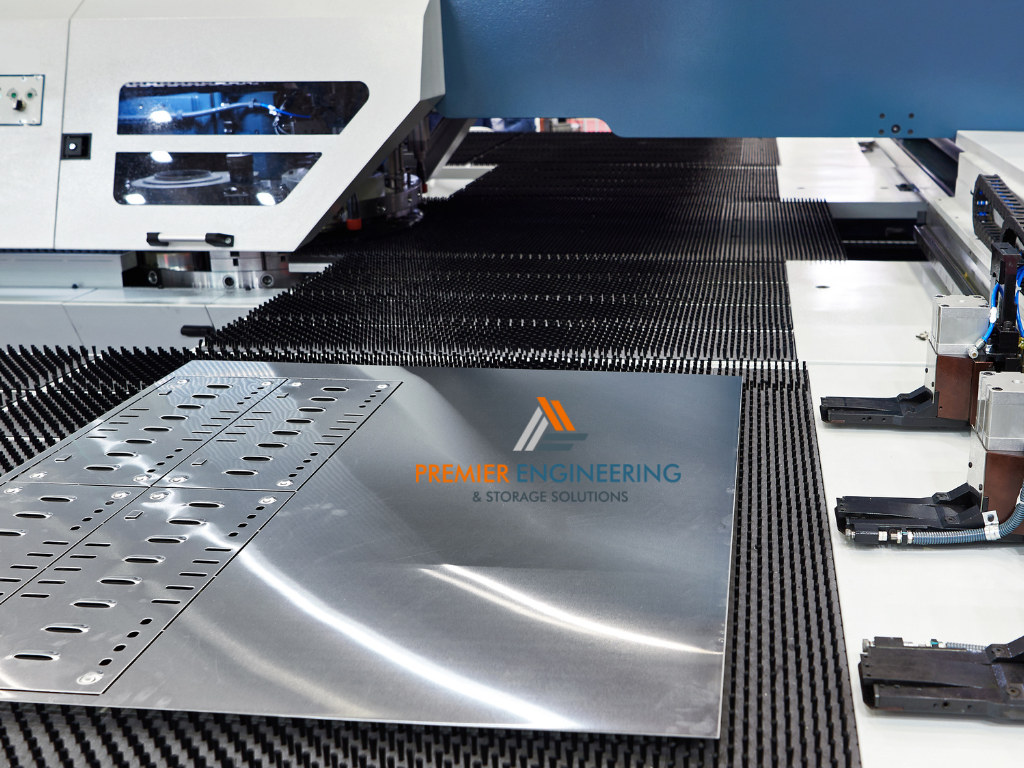

Another reason for its accuracy is stability. The machine holds the material firmly in place during cutting, which reduces movement and vibration. This makes cuts cleaner and sharper. With less chance of human error, the finished product has a higher level of quality that clients can immediately notice.

Why it reduces errors in production

Mistakes in production can cost time, money, and materials. A small error in manual cutting may mean scrapping an entire sheet of metal or starting a design again. With a cnc cutting machine, these errors are greatly reduced. The digital program can be tested and adjusted before cutting begins, which helps avoid waste.

This process also improves efficiency. Because the design is stored in the computer, the same program can be used to create multiple copies without variation. That means large orders can be completed with the same level of precision as a single prototype.

For businesses, fewer errors mean more reliable outcomes. For clients, it means getting consistent, high-quality products every time. By reducing waste and mistakes, a cnc cutting machine also helps lower overall costs, making it a smarter choice for both manufacturers and customers.

Faster results with a cnc cutting machine

How speed improves project timelines

A cnc cutting machine not only cuts with precision but also works at impressive speed. Traditional cutting methods often require more time for setup, adjustments, and manual handling. CNC machines, on the other hand, follow pre-programmed instructions that allow them to cut continuously with little interruption.

This means projects are finished faster and delivery deadlines are easier to meet. For businesses, this speed helps manage large orders without sacrificing quality. For clients, it means faster turnaround times and quicker access to finished products.

Why clients notice better consistency

Speed is not useful without consistency, and this is where the cnc cutting machine shines. Every part is cut the same way, whether it’s the first piece or the hundredth. This consistency ensures that final products fit together properly, meet design standards, and avoid quality issues.

Clients value this because it reduces the risk of rework and provides peace of mind that every order will meet expectations.

Comparing cnc cutting machine and laser cutting service

When a cnc cutting machine is the better choice

A cnc cutting machine is ideal for projects that require heavy-duty cutting, thicker materials, or repeat designs. Its strength lies in durability and reliability, making it a perfect choice for industries that work with metals, plastics, and wood on a larger scale.

For these types of projects, CNC often outperforms other cutting methods by maintaining strength and accuracy even in tough conditions.

How laser cutting service complements CNC work

A laser cutting service is best suited for delicate, intricate, and detailed designs. Laser beams can produce finer lines and are excellent for thinner materials. While a cnc cutting machine is powerful, laser cutting adds detail and flexibility.

Together, CNC and laser cutting service create a powerful combination that can meet a wide range of production needs.

The role of laser cutting in modern production

Why laser cutting is ideal for delicate designs

Laser cutting has become an important part of modern manufacturing because of its ability to create clean, intricate designs. The precision of a focused laser beam allows manufacturers to produce shapes and patterns that would be difficult to achieve with traditional cutting.

This makes laser cutting an excellent choice for custom projects, signage, and parts that need detailed finishing.

How it works alongside CNC methods

While laser cutting is excellent for detail, a cnc cutting machine is better for strength and larger-scale jobs. When both methods are used together, manufacturers can handle a wide variety of tasks, from small, artistic designs to industrial parts.

This partnership improves efficiency and offers clients more options to meet their needs.

Using an industrial steel cutting machine for stronger builds

Why strength and durability matter

An industrial steel cutting machine is used when projects require strong, long-lasting results. From construction parts to heavy equipment, the ability to cut steel with accuracy ensures that the final product is durable and safe.

Strength is especially important in industries where materials face high pressure or constant use. A reliable industrial steel cutting machine helps ensure quality is never compromised.

How CNC improves heavy-duty steel work

When paired with CNC technology, an industrial steel cutting machine becomes even more powerful. The computer control means cuts are accurate and repeatable, even on tough materials. This creates stronger builds that meet industry standards while reducing waste.

For those needing expert help, Premier Engineering & Storage Solutions is a manufacturing company where customers can get laser cutting, cnc punching, turret punching services, Metal punching services, Shelving Units and Storage Cabinets, and Machining. They combine advanced tools with experience to deliver high-quality results for industrial and commercial projects.

Turret punching services and cnc cutting machine working together

How turret punching services add flexibility

Turret punching services provide another layer of flexibility in production. This method uses a turret loaded with different tools to punch shapes, holes, or patterns into metal sheets. It’s fast, efficient, and perfect for designs that need repeating shapes.

When combined with CNC, it ensures every punch is placed exactly where it should be, improving accuracy and quality.

Why combining methods improves end results

By combining turret punching services with a cnc cutting machine, manufacturers can create products that are both strong and detailed. Each method has its strengths, and when used together, they cover a wider range of production needs.

This means clients get durable products without losing out on design flexibility.

Why product quality improves with cnc cutting machine use

Benefits for businesses and clients

The use of a cnc cutting machine leads to better product quality because it combines speed, precision, and consistency. Businesses benefit from reduced waste, faster delivery, and fewer mistakes. Clients benefit by receiving products that are accurate, reliable, and built to last.

This level of quality builds trust and strengthens long-term relationships between manufacturers and customers.

Why CNC technology leads to long-term reliability

CNC technology continues to improve, and its reliability is unmatched in many industries. A cnc cutting machine doesn’t tire, make mistakes, or lose focus. It delivers the same high-quality results every time.

This reliability means businesses can confidently take on more complex projects, knowing that product quality will remain consistent from start to finish.