Acrylic fabrication is the process of cutting, bending, shaping, or joining acrylic sheets to create strong, clear products. This method has been used for decades in industries like retail, construction, signage, and home décor. Acrylic is valued for its strength, transparency, and versatility, which is why it is often seen in display cases, panels, and protective barriers.

On the other hand, 3D printing builds objects layer by layer from digital models. Instead of starting with sheets or blocks of material, it adds material in thin layers to create a full product. This makes it ideal for custom prototypes or complex shapes that would be difficult to cut from a flat sheet.

Unique Strengths for Different Projects

Each method has its advantages. Acrylic fabrication is fast, precise, and produces items that are durable and clear, making it perfect for practical, everyday products. 3D printing, meanwhile, shines when it comes to creating unique shapes or testing new designs. Knowing the difference helps businesses and individuals choose the right tool for their project.

The Role of Laser Cutting Western Sydney in Acrylic Fabrication

Precision That 3D Printing Can’t Always Match

When it comes to accuracy, Laser Cutting Western Sydney services stand out. Laser beams can cut acrylic sheets into exact shapes with sharp edges and fine details. This makes them perfect for signs, panels, and even intricate decorative pieces. Unlike 3D printing, which may leave visible layers or rough edges, laser cutting creates a smooth finish right from the start.

Faster for Flat Designs

For flat or simple designs, laser cutting is often faster than 3D printing. While printing requires hours to slowly build each layer, laser cutting slices through sheets in minutes. This is why businesses looking for quick turnaround times often rely on acrylic fabrication instead of 3D printing. It saves both time and money, especially for bulk orders.

Why CNC Laser Cutting Supports Complex Designs

Turning Sheets into Custom Shapes

CNC laser cutting combines precision with automation. Using computer-controlled technology, machines follow digital designs to cut acrylic sheets into exact patterns. This makes it easy to produce clean edges and repeat the same design multiple times with no mistakes.

Comparing with 3D Printing

While 3D printing can also create complex shapes, the finish is not always as polished. Printed items may need sanding or extra work to look smooth, while CNC laser cutting produces professional results straight away. This makes acrylic fabrication the better choice when appearance and durability matter.

Comparing Speed: Laser Cutting Sydney vs 3D Printing

Which One Gets the Job Done Faster?

One of the biggest differences between the two methods is speed. Laser cutting sydney services are known for completing projects quickly, especially when large sheets of acrylic need to be cut into multiple pieces. Businesses that need signs, displays, or protective panels in a short time can depend on this method.

When 3D Printing Makes Sense

While 3D printing is slower, it has its place. It’s great for creating one-off prototypes or unusual shapes that cannot be made from flat acrylic sheets. However, if the goal is to make many items quickly and consistently, acrylic fabrication with laser cutting is usually the smarter option.

The Advantage of Perspex Cut to Size Sydney

Ready-to-Use Materials for Any Project

One of the biggest benefits of perspex cut to size sydney services is convenience. Instead of buying large sheets and cutting them yourself, you can order pieces already sized to fit your project. This saves time, reduces waste, and ensures you get accurate results every time. Whether you’re creating signs, displays, or protective panels, having perspex prepared in the right size makes the process easier and more efficient.

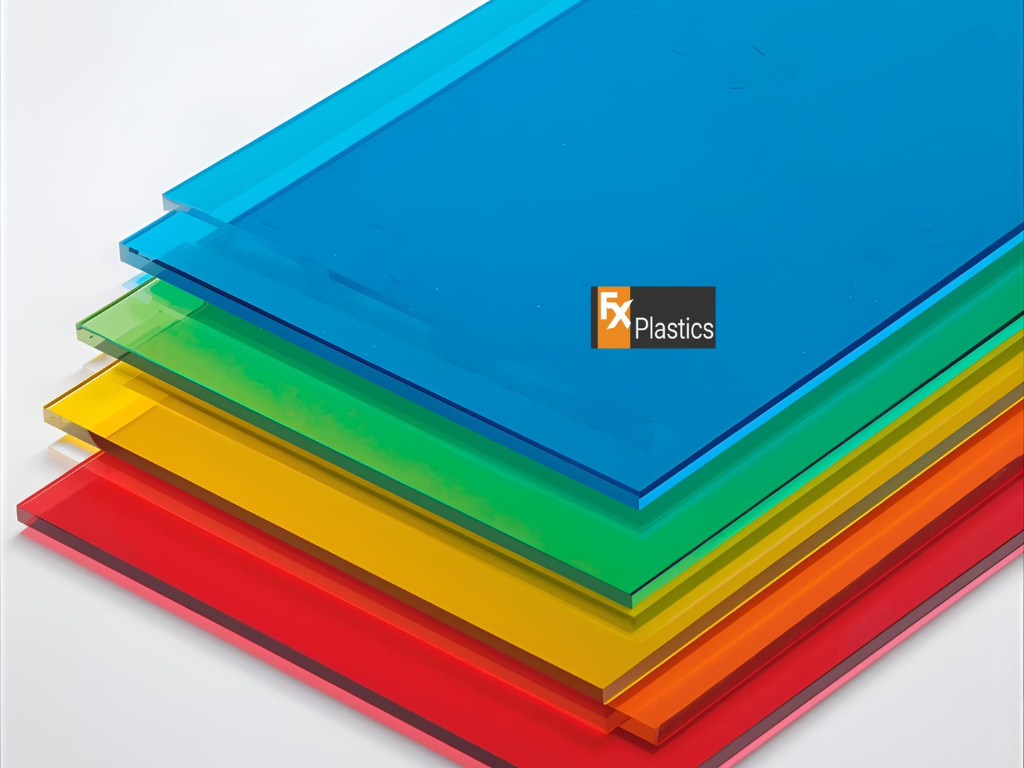

Partnering with Local Experts

This is where working with trusted companies makes all the difference. FX Plastics is an Acrylic Fabrication company where you can get custom cut acrylic in different colours, sizes, and thicknesses. They also provide CNC laser cutting, CNC Routing, and Machining, giving you access to professional tools for high-quality results. By using tailored services, businesses can focus on design and creativity without worrying about cutting errors.

Acrylic Screens and Practical Everyday Use

Strong, Clear, and Easy to Make

Acrylic screens are one of the most common products made through acrylic fabrication. They’re lightweight yet durable, and their transparency makes them perfect for offices, retail stores, schools, and even restaurants. Compared to 3D printing, producing acrylic screens with fabrication is far faster and more cost-effective.

Affordable Protection with Style

Since acrylic screens are easy to customise, businesses can order them in different shapes and sizes. This makes it simple to balance both safety and style. They’re widely used for counter barriers, room dividers, and display covers, offering a clear solution that also looks professional.

Choosing Between Acrylic Fabrication and 3D Printing

Picking the Right Tool for the Job

When deciding between Acrylic fabrication and 3D printing, it’s important to think about your goals. If you need clear, durable, and polished products in larger numbers, fabrication with laser cutting is the best choice. On the other hand, if you’re testing a prototype or need a unique shape, 3D printing could be the right fit.

Balancing Speed, Cost, and Finish

Both methods have value, but they serve different needs. Acrylic fabrication is faster, more cost-effective, and gives a professional look, while 3D printing is slower but offers flexibility for unusual designs. By weighing speed, finish, and budget, businesses can choose the right method and get the best results.