A cnc punching service is all about cutting or shaping metal sheets using a punch-and-die system guided by a computer. “CNC” stands for Computer Numerical Control, which means every move is controlled by a digital program. This makes the punching extremely precise and repeatable—even on large batches of metal.

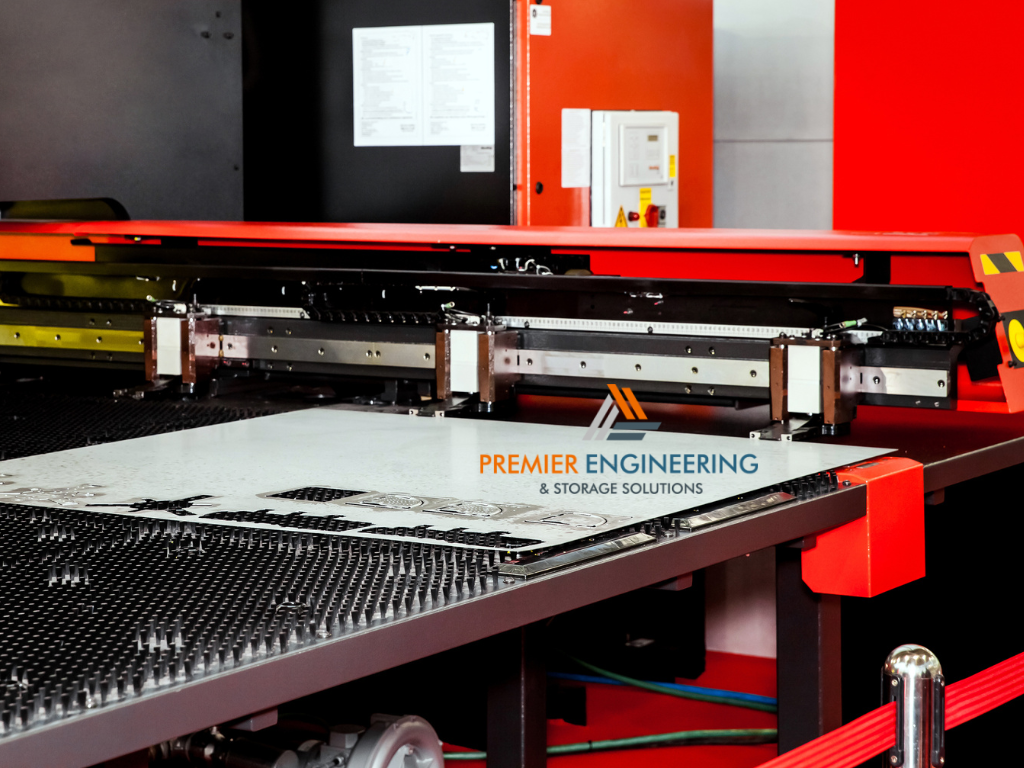

The machine punches holes, slots, or custom shapes into sheet metal using sharp tools and downward pressure. The sheet sits on a flat surface while the punch drops down to make clean cuts. Because it’s computer-controlled, the machine knows exactly where to punch and at what size. You get reliable results every time—no guesswork needed.

Fast, Accurate, and Made for Large Runs

One of the biggest reasons businesses choose a cnc punching service is speed. These machines work fast and can punch out hundreds of parts in a short time. That makes them ideal for high-volume production or custom orders that need many identical parts.

Even better, the process doesn’t sacrifice quality. The cuts are smooth, consistent, and often require little to no finishing work. Plus, the design can be changed quickly just by updating the program—no need to change tools for every new part. This saves time, lowers costs, and helps get products to market faster.

Overall, a cnc punching service offers smart, efficient metal processing that works well for industries like manufacturing, construction, signage, and more.

How Do Turret Punching Services Add More Efficiency?

One Machine, Many Tools

Turret punching services use a special kind of machine with a rotating tool holder, or “turret.” This turret holds many different punch shapes and sizes. Instead of changing tools for each new hole or design, the machine simply rotates the turret to switch tools on the go. That means faster setup and quicker job completion.

Better for Complex and Multi-Cut Jobs

If your design needs several different shapes, slots, or perforations, turret punching services are perfect. The machine works quickly, switching between tools in seconds. It’s great for cutting time on large or complex sheets where precision and variety matter. This kind of punching service speeds up production without losing quality.

Are Metal Punching Services Just for Cutting Holes?

More Than Just Round Cuts

Many people think Metal punching services are only for creating circular holes. That’s far from the truth. Today’s punching machines can produce various shapes—squares, rectangles, keyholes, and even decorative patterns.

Ideal for Fabrication Prep

Besides hole punching, these machines can also make indents, louvers, or guide marks. These extras are helpful for assembly or further fabrication steps. That’s why Metal punching services are often the first part of a full production process. They help set the stage for welding, bending, or other finishing touches.

Can CNC Cutting Services Follow After Punching?

Clean Finishes After Punching

After the metal is punched, it may still need trimming, refining, or final shaping. This is where cnc cutting services come in. These machines cut with extreme accuracy and are often used after punching to clean up edges or make custom contours.

Good for Detailed Work

CNC cutting services are excellent when parts need more than just holes. They can create curves, corners, or even engravings that punching alone can’t achieve. Pairing punching and cutting ensures both speed and detail—ideal for custom or premium-quality fabrication jobs.

Why Laser Cutting Service Is Often Paired with Punching

Best of Both Worlds

A laser cutting service is often used alongside punching because the two methods complement each other. Punching is great for speed and volume. Laser cutting adds precision, fine details, and clean edges—especially in tight corners or delicate patterns.

One-Stop Fabrication with Premier Engineering & Storage Solutions

At Premier Engineering & Storage Solutions, you can find both options under one roof. They offer full-service fabrication including laser cutting, cnc punching, turret punching services, and Metal punching services. Whether you need simple shapes or complex metal work, they’ve got you covered. They also provide Shelving Units and Storage Cabinets, Machining, and more—all tailored for your industrial or commercial needs.

What Other Fabrication Steps Follow CNC Punching?

From Flat Metal to Finished Product

Punching is often just the beginning. After using a cnc punching service, shops usually move to processes like bending (with a press brake), welding, and surface finishing. These steps turn flat sheets into real parts like brackets, enclosures, or structural pieces.

You Don’t Have to Do It All Yourself

The best part? You don’t have to manage each step separately. Full-service shops handle it all. They combine punching, cutting, and finishing in-house. That saves you time, money, and coordination headaches. Just send your design—and they’ll handle the rest.

How to Choose a Fabrication Shop That Offers It All

Ask the Right Questions

When looking for a metal fab shop, ask if they offer cnc punching service and other options like turret punching services, cnc cutting services, and laser cutting service. This ensures they can handle different needs and projects with fewer delays.

One Shop = Better Results

Choosing a single provider for all services brings many benefits—faster turnaround, fewer errors, and easier communication. Plus, it often lowers the total cost. Shops that offer full services tend to be more experienced, better equipped, and more efficient for your next job.