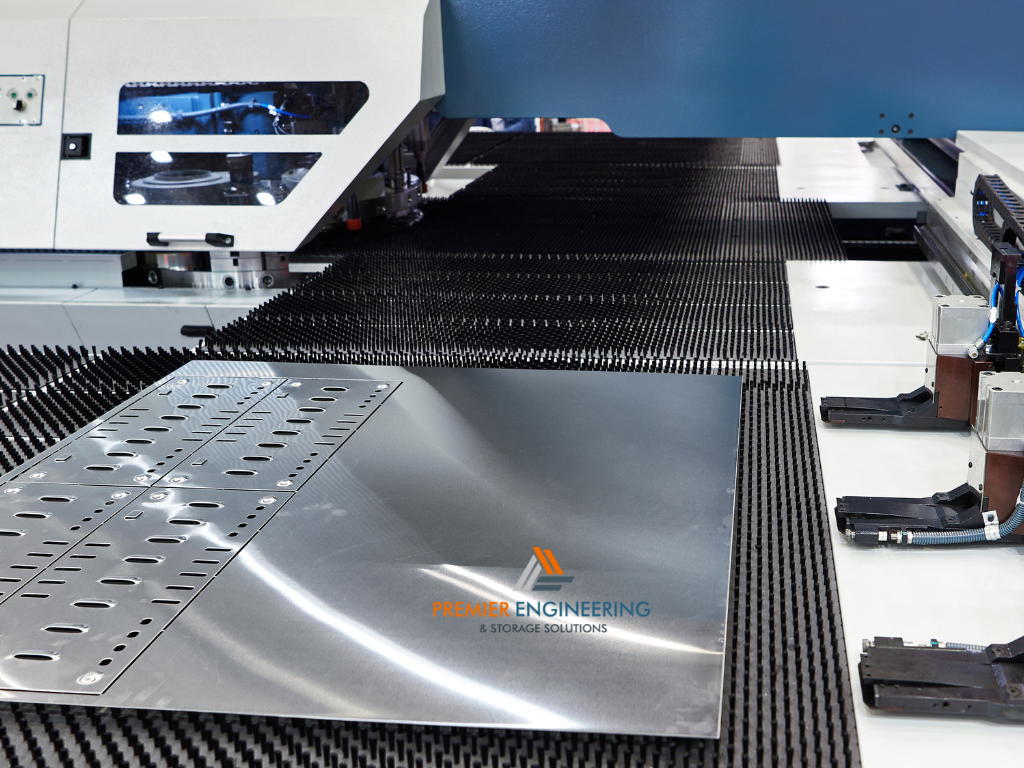

When it comes to precision and efficiency, turret punching services play a major role in modern sheet metal fabrication. This process uses a computer-controlled machine with a rotating turret that holds multiple tools. Each tool can punch holes, slots, or custom shapes into metal sheets quickly and accurately.

Because the turret can change tools in seconds, it allows fabricators to create complex designs without stopping production. This efficiency makes turret punching ideal for manufacturing control panels, enclosures, brackets, and other components that require consistent precision.

Why Turret Punching Is Essential in Metal Fabrication

Turret punching stands out for its speed and versatility. Unlike manual punching, it eliminates human error and allows large batches of parts to be made in less time. The process also reduces material waste by nesting parts efficiently — meaning fabricators can get the most out of every sheet of metal.

In industries like construction, electronics, and automotive, turret punching helps produce durable, uniform components that fit perfectly into larger assemblies. It’s a trusted process that combines strength, accuracy, and cost-efficiency — making it one of the foundations of today’s fabrication industry.

How Modern Engineering Manufacturing and Fabrication Capabilities Enhance Results

Smarter Machines and Automation

The rise of modern engineering manufacturing and fabrication capabilities has completely transformed turret punching. New machines now use automation and digital control systems to deliver faster results with better accuracy. Operators can upload digital blueprints directly into the system, and the machine automatically selects the correct tools and punch sequence.

This digital precision ensures consistency from the first part to the last. Advanced sensors even monitor the process in real-time, reducing downtime and preventing tool wear or material misalignment.

Boosting Efficiency with Digital Integration

Modern engineering manufacturing and fabrication capabilities go beyond speed — they focus on smart production. With the help of artificial intelligence and data analytics, turret punching machines can now adapt automatically to changes in material thickness or shape requirements.

The integration of digital software means less setup time, more accuracy, and reduced production costs. This combination of technology and engineering expertise ensures that every piece produced is reliable, high-quality, and ready for immediate use.

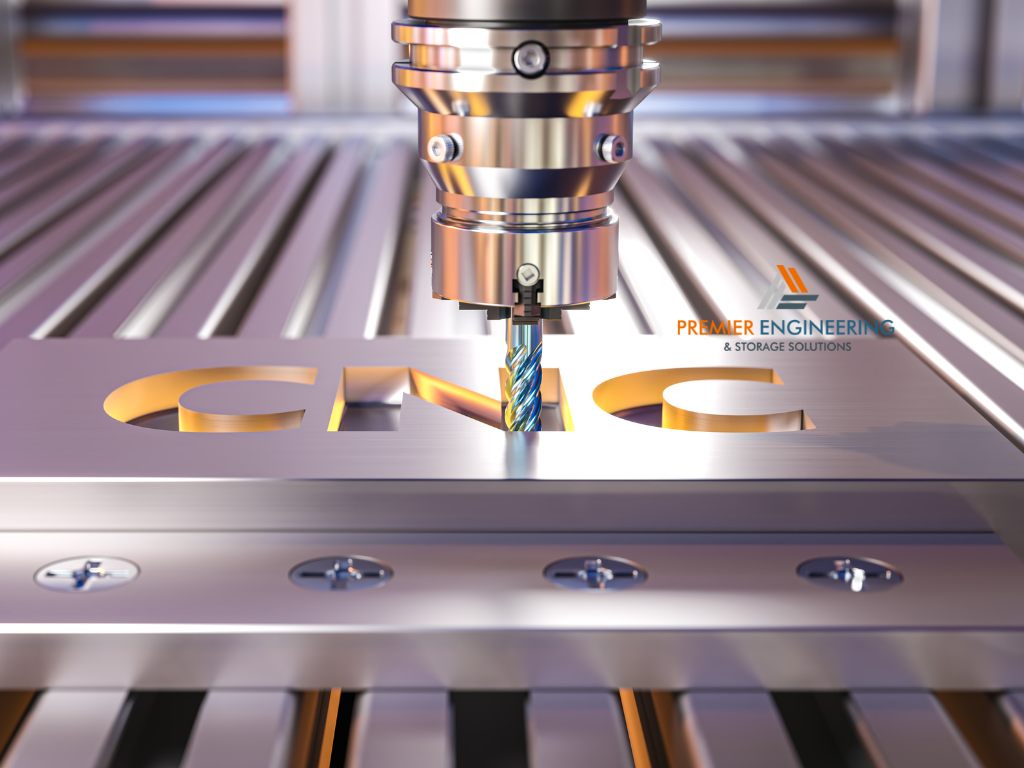

Precision and Productivity Through CNC Cutting Services

Working Together for Better Results

While turret punching is great for shaping and perforating, cnc cutting services enhance the process by refining edges and final details. CNC cutting allows fabricators to achieve clean finishes on every part, ensuring pieces fit together seamlessly. By combining both methods, manufacturers can produce parts that are accurate, smooth, and ready for assembly right after cutting.

This combination is widely used in industries like construction, transport, and electronics — where precision matters most. The accuracy of cnc cutting services ensures that even the most complex designs can be achieved with minimal rework or material waste.

Why CNC Cutting Adds Value

CNC cutting also offers versatility in working with different materials. Whether it’s aluminium, mild steel, or stainless steel, these services allow custom designs to be produced efficiently. The precision of CNC systems ensures tight tolerances, perfect dimensions, and consistent quality — batch after batch.

When turret punching services and CNC cutting are used together, manufacturers get the best of both worlds: fast production and high precision. It’s a combination that keeps fabrication efficient and cost-effective without compromising quality.

Comparing Turret Punching with Laser Cutting Technology

How Each Method Works

When comparing turret punching services to laser cutting, it’s easy to see that both have their strengths. Turret punching uses mechanical force to punch holes and shapes through a metal sheet, while laser cutting uses a focused beam of light to melt or vaporise material with extreme precision.

Turret punching is faster and more cost-efficient for repetitive shapes or large batches. It’s also great for creating holes, slots, and embossed patterns. On the other hand, laser cutting service is ideal for projects that require intricate details or smooth edges. It’s slower but delivers cleaner cuts and more flexibility for custom designs.

Choosing the Right Fabrication Process

The best choice depends on the job. For large-scale production or standard components, turret punching is unbeatable in speed and economy. If the design includes complex curves, engravings, or very fine details, laser cutting service is the better option.

Many manufacturers now combine both technologies to take advantage of each — turret punching for structure and laser cutting for precision finishing. This hybrid approach creates parts that are strong, precise, and efficient to produce.

The Role of CNC Stainless Steel Fabrication in Modern Projects

Why CNC Stainless Steel Is in Demand

When it comes to modern metalwork, cnc stainless steel fabrication has become one of the most sought-after solutions. Stainless steel is known for its strength, corrosion resistance, and professional appearance. By using CNC technology, manufacturers can produce stainless steel components that meet exact specifications while maintaining a smooth finish.

This process is essential for industries like architecture, construction, and transport — where reliability and appearance matter equally. Whether it’s custom brackets, kitchen surfaces, or heavy-duty enclosures, cnc stainless steel fabrication ensures precision, consistency, and durability.

Trusted Experts: Premier Engineering & Storage Solutions

For businesses needing advanced fabrication work, Premier Engineering & Storage Solutions is a reliable manufacturing company offering complete metal services. They specialise in laser cutting, cnc punching, turret punching services, and metal punching services — all performed using modern technology for accurate and high-quality results.

In addition, they provide durable shelving units and storage cabinets, as well as precision machining for industrial and commercial projects. Their expertise ensures every component is built with strength, efficiency, and long-lasting performance in mind.

Saving Time and Costs with Efficient Sheet Metal Production

Faster Setup, Less Waste

One of the biggest advantages of turret punching services is efficiency. Once a design is programmed, it can be reused again and again without additional setup. This means repeat orders are faster and more affordable. The process also minimises waste by optimising the sheet layout — getting the most parts from every piece of metal.

Compared to manual fabrication, turret punching reduces production time by up to 50%. This allows companies to meet deadlines faster while keeping prices competitive.

Smart Programming for Repeated Accuracy

Digital design files used in turret punching services ensure consistent results from the first part to the last. Every piece matches perfectly, reducing the need for post-production adjustments. For large-scale manufacturers, this accuracy means fewer rejections and smoother assembly processes.

In today’s fast-paced manufacturing world, saving time means saving money — and turret punching delivers both without sacrificing quality.

The Future of Turret Punching in Smart Manufacturing

Automation and Digital Control Lead the Way

The future of turret punching services lies in automation and smart technology. Modern machines are already integrating robotics and sensors that can monitor performance in real time. These systems can predict maintenance needs, reduce downtime, and maintain consistent production rates without manual supervision.

This evolution is part of a broader shift toward connected manufacturing — where every stage, from design to final assembly, is digitally controlled.

Blending Innovation with Sustainability

As sustainability becomes more important, engineering manufacturing and fabrication capabilities are evolving to reduce waste and energy use. CNC and laser systems now consume less power and produce fewer emissions, supporting cleaner, more efficient production.

In the years ahead, turret punching services will remain a vital part of smart manufacturing. With new tools, greener technologies, and digital precision, the industry is set to produce stronger, more sustainable results than ever before.